microballmill

Micro Ball Mill Gt300 China Grind and Mill Madein

The Micro ball mill GT300 is designed for modern laboratory applications It can process small amount and large batch sample, for example: plants, animal tissue and small The Micro ball mill MBM300 is designed for modern laboratory applications It can process small amount and large batch sample, for example: plants, animal tissue and small Micro Ball Laboratory Mill MRCLab

Ball mill Beijing Grinder Instrument Co,Ltd

Ball mill CryoGrinder LM200 Batch capacity:01100g precooling chamber:400ml Grinding chamber:200ml Learn More High Throughput Tissue Mill GT50 Frequency:9001800rpm Clamp Movement:34mm2022年12月1日 Therefore, in order to exert the microgrinding function of CBN particles, a 02 mm diameter PCBN micro ballend mill is designed with a spherical flank structure (MSPBM) as shown in Fig 1 This mill has five cutting edges, and the spherical flank structure makes each cutting edge have a 0° relief angle ThisDevelopment of PCBN micro ballend mill with multiedge

Micro End Mills McMasterCarr

Undercutting End Mills A fine point tip cuts lettering and numbering and makes designs in a variety of metals and composites, such as aluminum, fiberglass, and titanium Choose from our selection of micro end mills, including carbide square end mills, carbide ball end mills, and more In stock and ready to shipDownload The Mixer Mill MM 400 is a true multipurpose mill designed for dry, wet and cryogenic grinding of small volumes up to 2 x 20 ml It mixes and homogenizes powders and suspensions with a frequency of 30 Hz Laboratory Mixer Mill MM 400 RETSCH

Micro laboratory ball mill, GT300 – ProSciTech

The Micro ball mill GT300 efficiently mixes and homogenizes powders and suspensions within a matter of seconds It is capable of processing both small amounts and large batches of samples, such as plants, animal tissue, and samples with limited quantities, under dry, wet, or cryogenic conditions Additionally, it is ideal for disrupting 2016年11月3日 Micro ball end mill considered in the present work is a twofluted tool with 04 mm diameter and 05236 rad helix angle (β) The normal rake and clearance angles are taken to be zero and 02094 rad respectivelyStudy of micro ball end mill geometry and measurement of

Preparation of microsize flake silver powder by planetary ball mill

2015年9月21日 Flake silver powder with controllable particle size and specific surface area was prepared using planetary ball mill by varying milling parameters including milling time, revolution speed, and the weight ratio of balls to powder (BRP) Asprepared flake silver powder was characterized by laser particle analyzer, scanning electron microscope, X The Micro ball mill GT300 is designed for modern laboratory applications It can process 2 pcs and large batch samples simultaneously in 30 seconds, the sample volume from 02ml to 50ml It meets the requirements of high throughput grinding extremely Working PrincipleMicro Ball Mill Gt300 China Grind and Mill Madein

Microcut Carbide Micro End Mills

Microcut is a manufacturer of Premium Quality Carbide End Mills and Special Application Rotary Cutting Tools for industrial and medical applications Micro End Mills 2Flute; 3Flute; 4Flute; High Performance End Mills Variable Helix; Corner Radius; Profile Ball; Ball Mills; Spherical Ball Mills; HiPerf Aluminum; HiHelix; Die Sinking 3 天之前 The Micro Mill has effortless, chatterless, table and millhead movement due to the unique design of oversized gibs, ground ‘Y’ axis steel ways, and a massive carriage assembly Sealed precision ball bearing 5019CR Micro Mill TAIG Tools

Design and fabrication of a new micro ballend mill with

2018年3月27日 Micro ballend milling is an efficient method for the fabrication of micro lens array molds However, it is difficult to meet the machining quality of micro dimple molds due to the wear and breakage of the milling cutter, which presents large challenges for designing geometric structure and edge strength of micro ballend mills In this study, a new powerful grinding and homogenization micro ball mill The Micro ball mill GT300 is designed for modern laboratory applications It can process small amount and large batch sample, for example:plants, animal tissue and China Powerful grinding and homogenization

Analytical modelling and experimental validation of microball

2020年6月19日 In this paper, an analytical model for estimating the microballend milling forces is presented based on experimental investigation of progressive tool flank wear The wear form and wear mechanism of the microballend mill are revealed through a series of microballend milling experiments The effecting laws of cutting parameters such as feed FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of applications and Planetary Micro Mill PULVERISETTE 7 premium

Micro Ball End Mills [Miniature] The Carbide End Mill Store

Micro ball end mills or "micro ball nose end mills" are single end, general purpose mills used for making full radiused grooves, generating large corner radii, or contour profile milling The term "general purpose" means that the mills are manufactured with a 30° helix angle and are center cutting Mini ball end cutting tools are generally 2022年12月1日 In order to achieve higher machining quality and longer tool life, a PCBN micro ballend mill structure with multiedge and spherical flank face (MSPBM) is designed This structure enables Development of PCBN micro ballend mill with multiedge

Investigation on micromilling of cemented carbide with ball

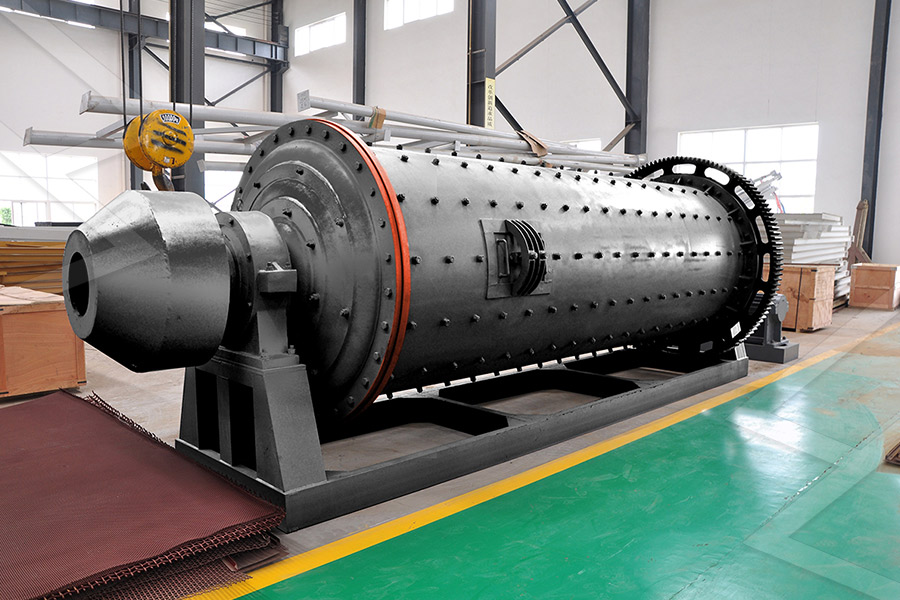

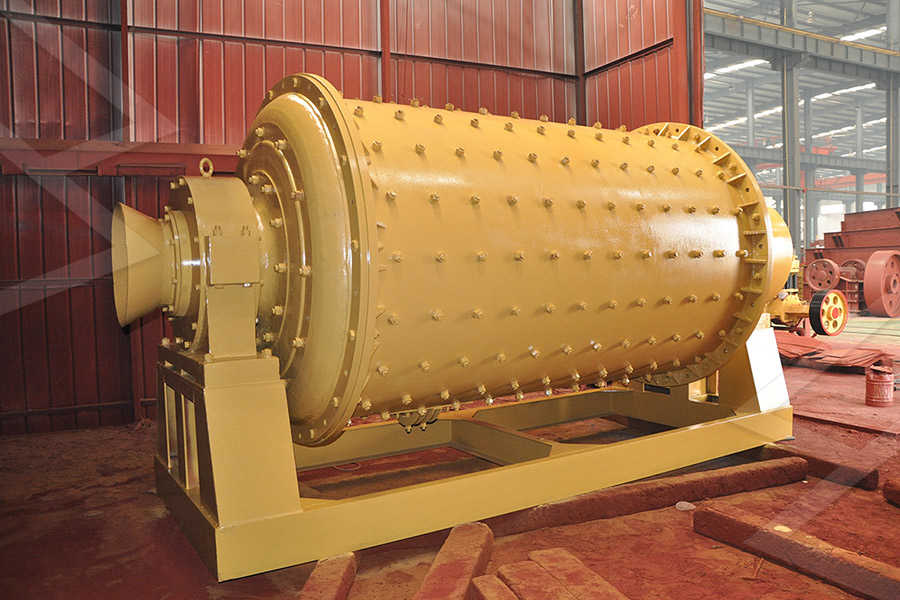

2024年2月7日 Two distinct tool geometries were employed in this study: (i) a microbull nose end mill with a tip radius of 01 mm, herein referred to as “bull nose”, and (ii) a twoflute microball end mill, herein referred to as “ball nose”, with a 05mm tool radius (refer to Fig 2b and d), both with a 1mm diameter Their geometry is described in Table 18322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect Topics

Research on the Milling Performance of MicroGroove Ball End Mills

2024年6月4日 Milling experiments showed that microgrooved ball end mills help reduce milling forces, achieving good simulation consistency When using a cutter with three microgrooves, the milling force decreased by 10% to 30%, and the surface roughness decreased by 8% to 12% It was also found that as the spindle speed increases, the curling radius of 2020年3月1日 To calibrate and validate the effectiveness of the proposed cutting forces model, the same twoflute solid carbide micro ballend mill (SECO A64T) with wearvarying cutting edge under different wear stage adopted in Section 31 is introduced to perform the slot milling experiments on NAK80 steel shown in Fig 16 The spindle speed Semianalytic modelling of cutting forces in micro ballend

Manufacture and application of ultrasmall micro end mills

2012年1月1日 It is also possible to machine micro end mills with a dovetail profile and micro ball end mills as well as micro end mills with different helix angels (see Fig 6) Download : Download fullsize image; Fig 5 Micro end mill D = 10 μm and D = 20 μm Download : Download fullsize image; Fig 6 Process geometrical freedomAiming at grinding quality control problem of the 05 mm diameter polycrystalline diamond micro ballend mill, based on the geometric motion principle of sixaxis machine, a mathematical model for the grinding of PCD micro ballend mill is established, orthogonal experiments are carried out to study the influence of the grinding parameters on the Optimization of edgegrinding parameters of polycrystalline

Preparation of microsize flake silver powder by

2017年8月29日 The transformation in particle micromorphology and size of Ag was carried out by planetary ball mill (QM1SP2) in a agate jar using agate balls of 2–6 mm diameter Figure 1 shows a schematic diagram of the planetary ball mill [6] During the preparation process of flake silver powders by planetary ball mill, every time the ball mill adopts4 天之前 MiniSeries The compact, universally applicable laboratory circulation mills of the MiniSeries impress with easy handling and the use of small quantities from 025 to 05 l for product sizes down to the MiniSeries / MicroSeries laboratory mills

Structural design and fabrication of polycrystalline

2020年6月15日 Fig 1 Micro ballend mill plane cutting edge curve 1900 IntJAdvManufTechnol(2020)108:1899–1911 The mathematical model of the plane cutting edgeiscreated based on the space vector, as shown in Fig 1 Firstly, the O dX dY dZ d tool coordinate system is created The P C is the마이크로 볼밀 Micro Ball Mill GT300 은 다양한 종류의 소량 샘플을 단 시간에 분쇄, 균질화하는 장비입니다 수 초 내로 분말과 현탁액을 혼합하고 균질화할 수 있습니다 또한 DNA / RNA 및 단백질 추출, 생물학적 세포의 파괴 에도 적합합니다마이크로볼밀 Micro Ball Mill GT300 실험실 분쇄기 : 네이버

Development of PCBN micro ballend mill with multiedge

2022年12月1日 Therefore, in order to exert the microgrinding function of CBN particles, a 02 mm diameter PCBN micro ballend mill is designed with a spherical flank structure (MSPBM) as shown in Fig 1 This mill has five cutting edges, and the spherical flank structure makes each cutting edge have a 0° relief angle ThisUndercutting End Mills A fine point tip cuts lettering and numbering and makes designs in a variety of metals and composites, such as aluminum, fiberglass, and titanium Choose from our selection of micro end mills, including carbide square end mills, carbide ball end mills, and more In stock and ready to shipMicro End Mills McMasterCarr

Laboratory Mixer Mill MM 400 RETSCH

Download The Mixer Mill MM 400 is a true multipurpose mill designed for dry, wet and cryogenic grinding of small volumes up to 2 x 20 ml It mixes and homogenizes powders and suspensions with a frequency of 30 Hz The Micro ball mill GT300 efficiently mixes and homogenizes powders and suspensions within a matter of seconds It is capable of processing both small amounts and large batches of samples, such as plants, animal tissue, and samples with limited quantities, under dry, wet, or cryogenic conditions Additionally, it is ideal for disrupting Micro laboratory ball mill, GT300 – ProSciTech